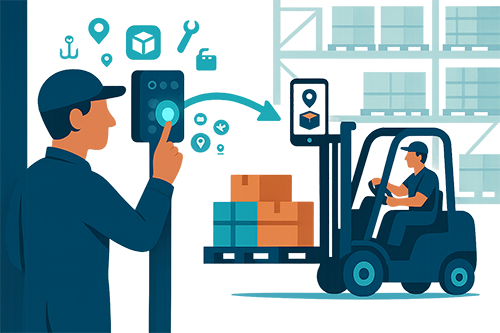

Connected Logistics Call Station

Optimize your replenishment flows with instant logistics calls in one simple click

Optimize your replenishment flows with instant logistics calls in one simple click

Simplified logistics calls for smooth, uninterrupted production

Line stoppages due to component or consumable shortages represent significant waste. With traditional methods, operators must leave their station, find a supervisor or make a call, creating delays and disruptions. Button Hop transforms this process by enabling instant reporting with a simple press on a dedicated button. The operator remains focused on their task while the alert is automatically transmitted to the logistics team, reducing production downtime by up to 70%.

Streamlined Production

70% reduction in production stoppages related to logistics waiting

Increased Productivity

Operators gain up to 20 minutes per station and per team

Optimized Flows

40% reduction in non-productive logistics movements

Data-Driven Decisions

Precise analyses to optimize stock levels and routes

Concrete applications for all your logistics needs

Place Button Hop buttons in strategic locations

Define actions to trigger and alert recipients

Your teams or customers press buttons according to identified needs

Analyze data to continuously improve your processes

Each Button Hop button can be configured to represent a specific need: raw material replenishment, finished product evacuation, forklift call, packaging needs, etc. The transmitted information is rich and complete: exact location (station, line, zone), type of need, precise timestamp, and even urgency level. This precision allows logistics to prioritize interventions and optimize routes, reducing unnecessary movements by 40% on average.

Button Hop doesn't just transmit requests - it creates a valuable database for logistics flow analysis. Each call is recorded with its context, processing time and resolution. This data enables identification of recurring friction points, optimization of stock levels accordingly, and measurement of logistics service performance. The created transparency promotes collaboration between production and logistics for continuous process improvement.

Button Hop radically modernizes traditional call systems (phones, intercoms, physical movements) by offering an instant, wireless and perfectly integrated solution. Unlike traditional methods that create interruptions, Button Hop enables asynchronous and contextualized communication. Information goes directly to the right people with all necessary details, eliminating back-and-forth and misunderstandings.

Absolutely! Each button can be configured to represent a specific need in your environment: raw material replenishment, finished product evacuation, forklift call, packaging needs, technical assistance, etc. You can customize icons, colors and labels for immediate recognition by your teams.

Notifications can be sent on multiple channels simultaneously according to your configuration: dedicated mobile application, SMS, email, notifications on collaboration tools (Teams, Slack), or display on supervision screens. You can define escalation rules if the request isn't processed within allotted timeframes.

Transmission is extremely reliable thanks to the LTE-M network dedicated to industrial connected objects. Even in difficult environments (metal buildings, shielded areas), the connection is maintained. In case of temporary network loss, the user is alerted by a light feedback.

Yes, Button Hop integrates perfectly with most warehouse management systems (WMS) and ERPs. Calls can automatically trigger work order creation, stock level updates, or picking route optimization. We have standard connectors and can develop specific integrations if needed.

The system allows defining multiple priority levels (normal, urgent, critical). Buttons can be configured with color codes and different processing rules. Urgent requests can trigger enhanced notifications and automatic escalations to managers.

Our clients generally see ROI in 3 to 6 months. Gains mainly come from reduced production downtime (up to 70%), optimized logistics workforce (15-25% more productivity), and stock reduction thanks to more reactive replenishment.