Digital Industrial Time Measurement

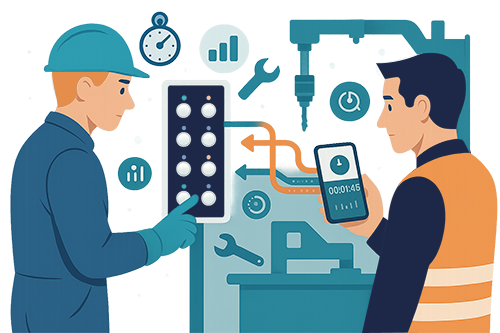

Simplify your time studies and optimize your processes with connected button time measurement

Simplify your time studies and optimize your processes with connected button time measurement

Move from tedious manual stopwatch to precise and automated digital time measurement

Traditional time measurement with manual stopwatch and recording sheet is extremely time-consuming and prone to errors. Observers must simultaneously handle the stopwatch, record times and identify operations, which generates inaccuracies and limits the amount of data collected. Button Hop eliminates this complexity by allowing operators to start and stop timers with a simple press on the button dedicated to each operation. Measurement becomes natural, integrated into the work process without disruption.

Intuitive Start/Stop

A dedicated button per operation to instantly start and stop the timer, without complex training needed for operators.

Automatic Categorization

Each button represents a specific operation (assembly, control, adjustment...), allowing immediate sorting and analysis of data by activity type.

Real-time Recording

All measurements are automatically saved with timestamping, eliminating risks of data loss or transcription errors.

Statistical Analysis

Automatic calculation of average times, standard deviations, distributions and other statistical indicators for robust performance analysis.

Up to 80% time saved on time data collection and analysis compared to manual methods

Measurements to hundredth of a second without human error, for reliable and objective standard times

Identification of bottlenecks and improvement opportunities based on massive and reliable data

Operators become actors in measuring and improving their own processes

Place Button Hop buttons in strategic locations

Define actions to trigger and alert recipients

Your teams or customers press buttons according to identified needs

Analyze data to continuously improve your processes

Each time measurement with Button Hop automatically captures a set of valuable information: timestamp, operation identification (via pressed button), workstation, operator, and production context. This data richness goes far beyond simple time recording and enables multidimensional analyses impossible with traditional methods. You can correlate times with manufactured products, teams, periods, and identify performance influencing variables.

The digitalization of time measurement transforms a one-time activity into a permanent improvement tool. Collected data feeds robust statistical analyses to establish reliable standard times, identify bottlenecks, and measure improvement impact. Performance deviations become visible in real-time, enabling targeted operator coaching and proactive revision of work methods. The entire organization benefits from a data-driven vision of operational performance.

Button Hop revolutionizes time measurement by making it digital and scalable. Unlike manual stopwatches that require constant observer presence, Button Hop allows operators to measure their own times naturally. Data is automatically enriched and the volume of measurements can be significantly increased for robust statistical analysis.

Absolutely! Button Hop adapts to all types of operations. For cyclical tasks, the same button can be used in a loop. For non-cyclical or occasional operations, specific buttons can be dedicated. The system's flexibility allows modeling complex processes with variable operation sequences.

Data is transmitted in real-time to our analytics platform where it's automatically processed: calculation of elementary times, sequence analysis, statistics by operation/operator/period. Interactive dashboards allow performance visualization and PDF reports can be automatically generated according to your needs.

Yes, Button Hop is perfectly adapted for machine cycle time measurement. Buttons can be positioned to mark cycle start and end. This approach allows analyzing equipment real performance and identifying micro-stoppages.

Our system allows contextualizing each measurement. Specific buttons can be used to identify operator changes, product changes, references or batches. This information is automatically associated with all following measurements until the next change.

Our clients generally see ROI in 2 to 4 months. Gains come from cycle time optimization (5-15% improvement), study time reduction (up to 80% savings), and faster identification of improvement points enabling significant productivity gains.